Rethinking Prefabrication: How System 600 is Pioneering a New Kit-of-Parts Approach to Australia's Housing Crisis

A groundbreaking research project is developing an innovative solution that could transform how Australia builds. System 600, a joint initiative between Homes NSW and the Building 4.0 CRC, represents a fundamental rethinking of Modern Methods of Construction (MMC) for the Australian market. Rather than following conventional prefabrication approaches, the project has developed what researchers call a "kit of parts" system that promises to deliver the benefits of manufacturing whilst maintaining design flexibility.

A Uniquely Australian Solution

"We've probably got the same ingredients that many others in the industry are working on, but we've got a slightly different recipe," explains Mathew Aitchison, Director of the Building 4.0 CRC. "The recipe is sort of tailor-made for the Australian market."

The system addresses a fundamental challenge facing Australia's existing prefabrication industry. Traditional modular construction requires massive capital investment in single facilities and typically locks clients into proprietary systems with limited design options. For Professor Daryl Patterson from Monash University, who leads the technical development, this creates an unsustainable risk concentration: "I don't think a lot of clients are comfortable with that idea that they've got to go to this super company with a super factory that's going to make everything."

Instead, System 600 leverages Australia's existing manufacturing capacity across a distributed supply chain. "We have a lot of capacity in the Australian industry," Patterson notes. "There's a lot of intelligence in the supply chain... So what if we just create the system that lets all those parties come together on a project with their standardised parts."

The Kit-of-Parts Approach

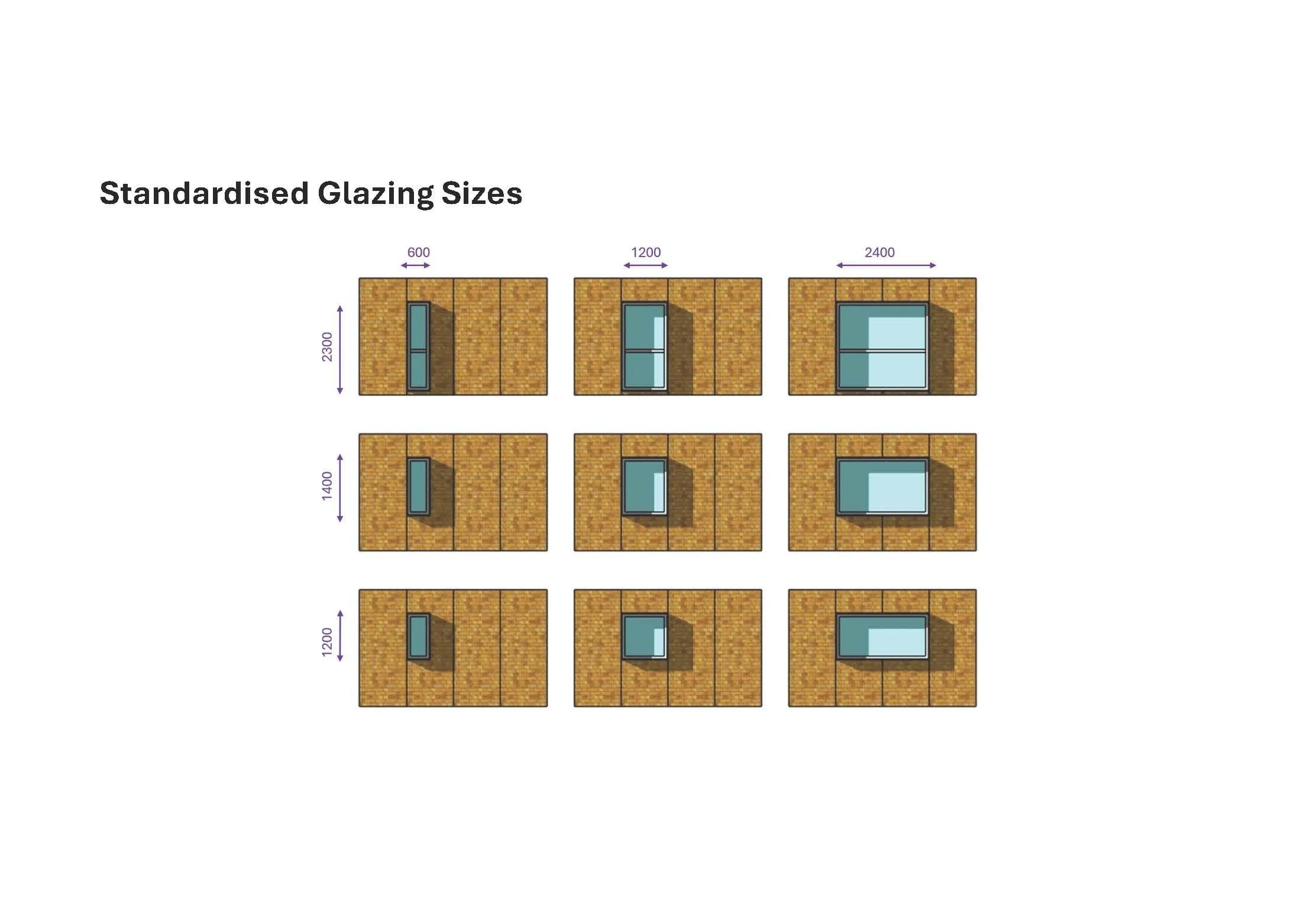

The innovation lies in breaking buildings down into standardised, interchangeable components rather than entire modules. Using what Patterson describes as a "Lego analogy" - though acknowledging buildings are far more complex - the system enables architects to combine standard parts in countless ways to create diverse designs.

"We have standard parts, not standard designs," Aitchison emphasises. "Those standard parts can be recombined in many different ways to create non-standard designs... You could walk down a street where both sides of this street have been made using this system, and you wouldn't know that because they would look completely different."

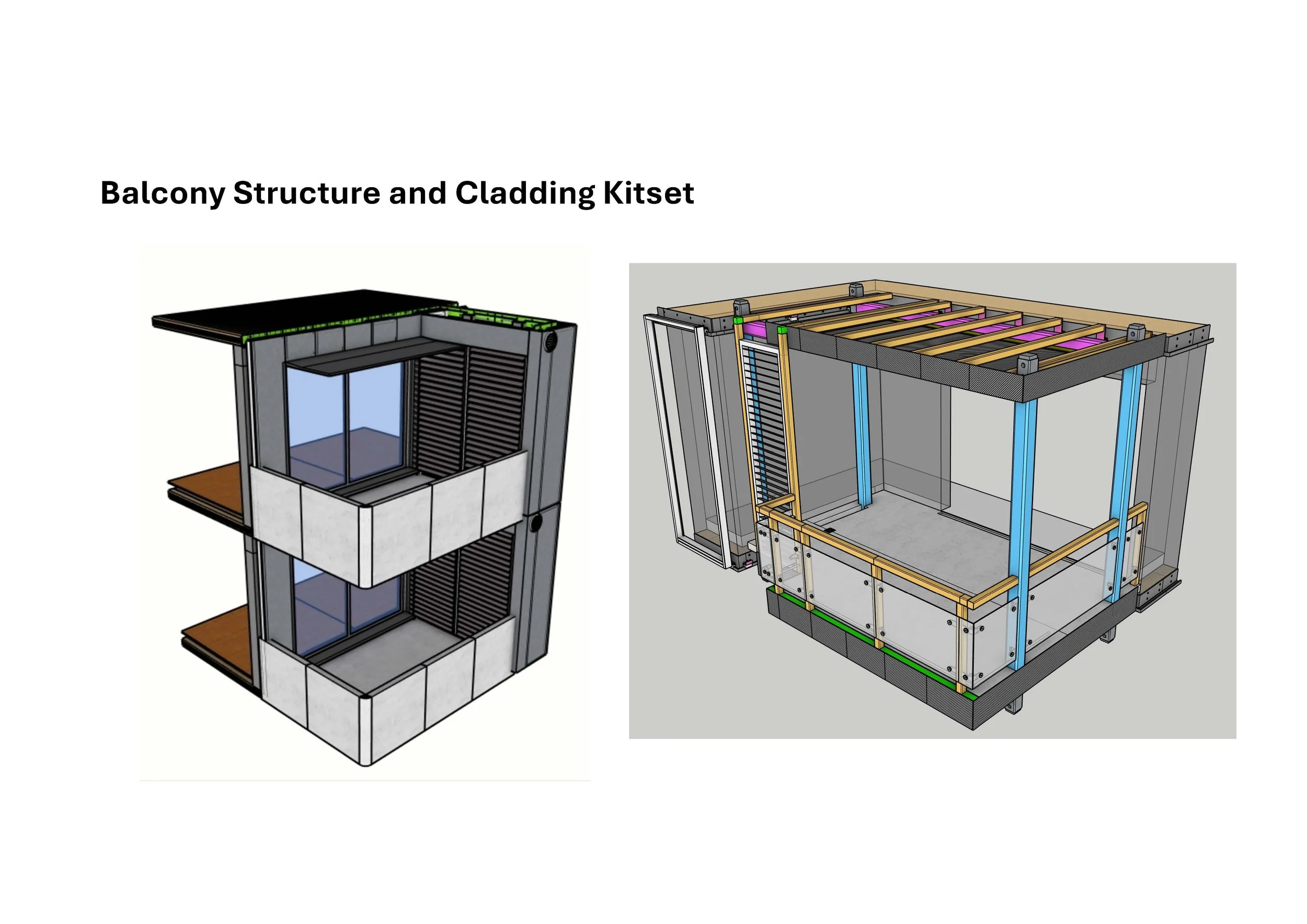

The system operates across four main subsystems: structure, exterior, services, and interior finishes. Rather than monolithic building elements, System 600 breaks components into multiple subsystems.

This decomposition is philosophically strategic - by breaking complex assemblies into discrete jobs, each component can be optimised for repeatability. A façade becomes separate layers handling water exclusion, thermal performance, and architectural expression independently. This approach may initially seem counterintuitive - adding more parts rather than fewer - but enables the critical shift from bespoke fabrication to standardised, scalable products that can be manufactured efficiently while maintaining design flexibility and a competitive supplier environment.

Economic Logic and Learning Effects

The economic rationale centres on achieving manufacturing-scale economies through repeatability. While individual buildings remain unique, the underlying components achieve massive scale across multiple projects. "We might be going to a particular manufacturer and saying, can you give us a thousand of these things?" Aitchison explains, describing how orders could scale from thousands to tens of thousands of identical parts.

This approach unlocks what researchers call "Wright's Law"—the manufacturing principle where costs decline by approximately 20% for every doubling of cumulative production. By standardising at the component rather than building level, System 600 can achieve these learning effects while maintaining architectural diversity.

Balancing Flexibility and Repeatability

The system's sophistication lies in its strategic distribution of complexity. "Can we make some parts really complicated so that the other parts can be really simple?" Patterson asks. Components are classified as "Fixed" (never changing, highly engineered), "Flexible" (adaptable within parameters), or "Free" (completely variable).

For example, the External Services Module represents a highly complex, fixed component that integrates hot water systems, air conditioning, electrical distribution, ventilation, data services, and even clothes drying into a single prefabricated unit. This complexity enables other building elements to be simpler and more adaptable.

The system targets approximately 80% standardised components with 20% site-specific elements, essentially reversing the current construction model, in which 80% of work happens on-site from scratch.

Implementation Strategy

The NSW Government has committed to ambitious targets, with Minister Rose Jackson indicating that 80% of buildings should use MMC content by 2030. System 600's implementation follows an incremental approach, gradually introducing products into existing Homes NSW projects to build supplier capability and demonstrate benefits.

"We call this approach incremental implementation," Aitchison explains. "We're not trying to suggest that from one day to the next, suddenly we just flip the switch... But we are saying we can introduce more and more products over time."

The strategy addresses procurement challenges that have historically hindered MMC adoption. By creating standardised products that can be ordered in volume, the approach enables competitive tendering whilst building the pipeline certainty manufacturers need for investment.

The Demonstrator Project

A demonstration apartment currently under construction in Mascot, NSW, showcases the system's potential. The project involves multiple Australian manufacturers—from modular wiring companies to bathroom pod specialists—and proves the distributed supply chain concept.

"We wanted to walk the talk," Patterson explains. "We distributed the work amongst a series of Australian established players who would generally do bespoke work for clients. And here we're saying, here's the first idea of a product."

The demonstrator will be exhibited in Sydney during Q3 2025, providing a tangible example of how standard components can create sophisticated, habitable spaces.

Looking Forward

System 600 represents more than a technical innovation - it's a new model for industry collaboration that could influence global prefabrication development. As Patterson observes, "having spent many years looking worldwide for these kinds of solutions, there are few compelling examples. But there is a train wreck of capital invested in things that just got nowhere."

For an industry facing unprecedented challenges, System 600 offers a pathway to harness manufacturing principles without sacrificing the diversity and adaptability that Australian housing demands. The project's success could provide a template for other markets grappling with similar productivity and supply challenges.

This article was originally published in the Smart Building Review Australia, the official publication of prefabAUS, Australia's peak industry body for prefabrication and Smart Building.